Seam Welding

Questions and Answers

A seam welding shaft is generally a large diameter copper alloy bar precision machined to conduct the current deliver force and rotate during the seam welding operation. The shaft works hard under heavy duty cycles, currents and forces. The shaft operates in a housing which is filled with conductive grease and has current carrying shoes which ride on the shaft to deliver current. Eventually these conductors and the shaft wear and service is required.

Shaft wear is more common than breakage but is possible.

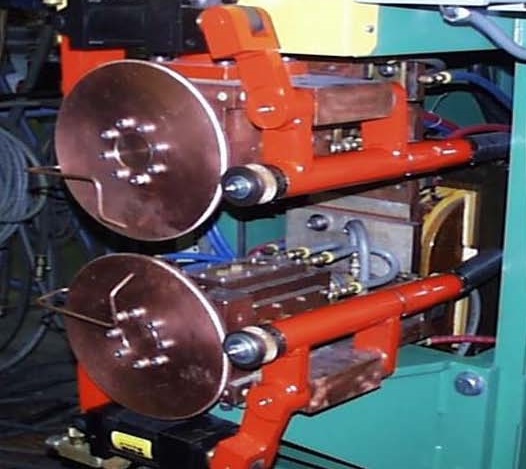

SEAM WELDER WITH KNURLERS

Some information for seam welding high nickel chrome iron alloys is published by the American Welding Society in their Welding Standards. Examples of current values that can work are exhibited there.

AWS Standard C1.1:2019 “Recommended Practices for Resistance Welding”

Information for seam welding stainless steel is published by the American Welding Society in their Welding Standards.

"AWS Standard C1.1:2019 “Recommended Practices for Resistance Welding”

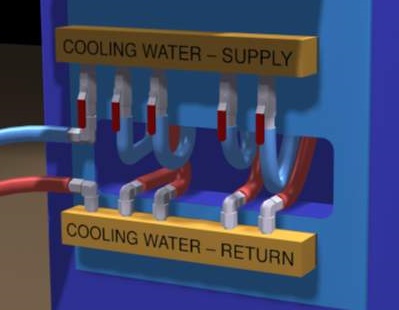

A seam welder has the same components as any other resistance welding machine. These components (transformer, conductors, control and electrodes) each require independent water cooling. Flow to these components should be as specified by the manufacturer. Normally the rates are 1-1.5 gallons/minute. The duty cycle of a seam welder runs higher than most other resistance welding applications making cooling imperative.

COOLING WATER MANIFOLD

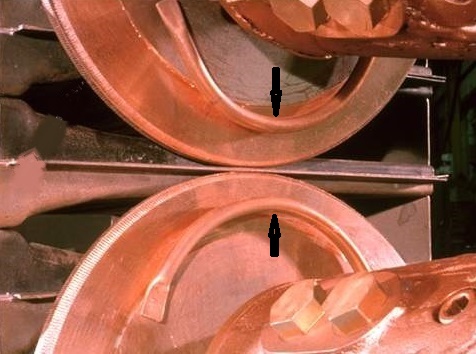

In addition to the normal internal component water cooling, water is frequently applied in a stream (flood cooling) directly at the weld location. This externally cools the seam welding wheels and part being welded. This flow should be at 1–1.5 gallons/minute.

ARROWS INDICATES EXTERNAL FLOOD COOLING WATER TUBES

FOR ADDITIONAL INFORMATION REFER TO OTHER ARTICLES IN THIS BLOG:

“WHAT IS THE PROPER AMOUNT OF WATER COOLING FOR SEAM WELDING?”

“IS THE WATER USED FOR SEAM WELDING HARMFUL AFTER BEING USED FOR COOLING?”

References: RWMA- RWMA Resistance Welding Manual 4th Edition

AWS- AWS Standard J1.2 Guide to the Installation and Maintenance of Resistance Welding Machines

It certainly is possible but may not be practical to convert a spot welder into a seam welder. Many major components will need to be examined and potentially redesigned or changed. This would include the transformer, conductors, machine weld head, control and plant input power to name a few. This conversion will involve the potential change from a standard electrode to a seam welding wheel and a rotating weld held mechanism. This is a major machine design change. This should be addressed with a machine builder or rebuilder of used machinery. This question is beyond the scope of this discussion.

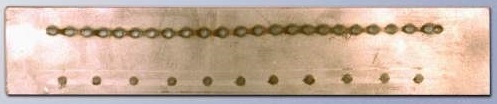

If one wants to use a spot welder to make spot welds close together. These are referred to as stitch welds.

VARY SPOT SPACING TO MAKE

A STITCH WELD

Page 4 of 15

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.