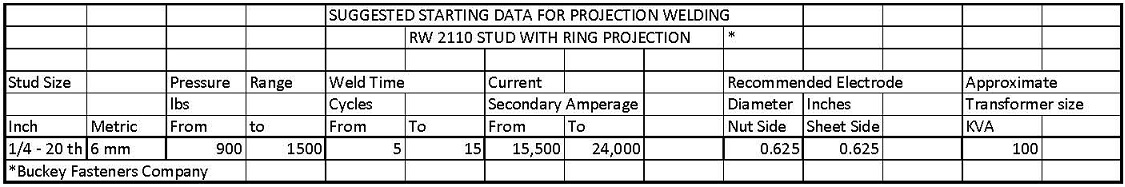

The RWMA Manual and AWS C1.1 and others do not offer any published weld schedules for projection welding ring projections. A manufacturer of studs does offer some input on the subject. The RW 2110 stud has a full ring projection on a ¼-20 (6mm) threaded bolt. The following information is available to use as a starting point:

For example this data could be used for welding studs to mild steel of various thicknesses including 0.063 or 0.075” (14 & 16 gauge). As with any weld schedule this could be the starting point. A machine or robot gun with about 100 KVA capability could be sought out for initial trials. In all projection welding good fast follow up equipment is needed to ensure set down of the ring projection. The various pressure weld times and currents should be used as starting points.

The safe way to start the initial test is always start below these settings and work up until the desired results are achieved. This will prevent damage to product, equipment or personnel.

When the desired results are achieved all of the welding criteria should be recorded on weld schedule data sheets including photos for your records and archived accordingly.

Other articles on this website on Projection weld schedules include:

How do you develop a Projection Weld Schedule?

What is follow up in Projection Welding?

How does alignment affect Projection Welding?

Welding parameters for Projection Welding?

References:

RWMA Resistance Weding Manual

AWS C1.1 – Recommended Practices for Resistance Welding

Buckeye Fasteners Company