This is an interesting question. It brings up part placement, accuracy, consistency and safety. The part needs to be loaded accurately each time and at the same time the operator must be safe. Safety will be briefly discussed here. There are a few general items that can be considered:

• Normally operators have eye protection and gloves for protection from flash or burrs on the metal components that may be handled

• Tooling or fixtures are common which accept the part components and hold them in the proper position and orientation prior to welding

• Auto loading mechanisms are frequently used to load parts (nut welding)

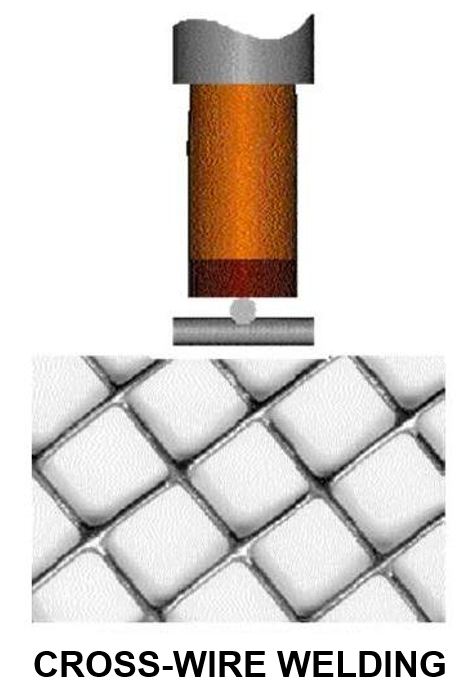

• Auto loaded or manual loaded, the parts must be positioned to ensure that the electrode force is perpendicular to the projections. The goal is even perpendicular force distribution. If the electrode is at an angle skidding may occur and weld strength may be compromised along with part distortion.

• Robotic systems frequently are used for part placement

• In manual loading, safety systems are employed to ensure that the operator is clear before the welder can be initiated.

• Robotic or Automatic systems are frequently enclosed in caged areas for safety

From a resistance welding point of view the part must be held or positioned in the proper orientation and alignment to meet the part specification. It must stay that way until the electrodes have closed on the part. Fixtures or tooling frequently perform this function.

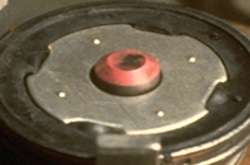

PIN LOCATING 4 PROJECTIONS

In some applications part desing fullfils this need

Parts are generally fixtured and loaded manually or with auto loading systems. This will allow for hands to be out of the weld area before weld activation. In manufacturing, safety systems are frequently employed to ensure hands have been removed before the weld cycle will activate.

Local machine manufacturers and suppliers will be familiar with the local regulations and available safety equipment for fixturing and personal protection.

Safety requirements vary. KNOW, UNDERSTAND and ADHERE to the prevailing Safety Standards in your location for manually loaded parts or auto loading systems.

Safety implementation is beyond the scope of this blog.

Reference: RWMA - Resistance Welding Manual 4th Edition