Resistance welding weld nuts is a projection welding process. In projection welding the part has been formed by design or shape to deliver the force and current at predefined generally small points, shapes or circles. In the case of weld nuts the power is delivered through several small points. Each projection will develop a normal weld nugget. This form of resistance welding uses the part to concentrate the heat and force not the electrode. The traditional weld cycle is squeeze, weld, hold. This is the same as a traditional spot weld. Preheats are not normally used in projection welds.

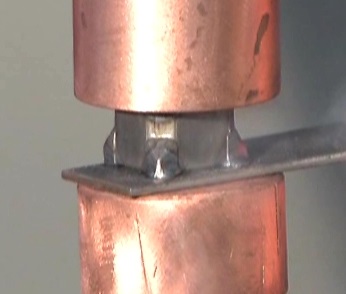

PROJECTION NUT WELD

Projections welds are normally very short fast welds. I did experience preheat once in a case where the weld nut had uneven projections and they were not setting down evenly. A very short preheat allowed the projections to align themselves before the main welding current initiated and all four projections then produced good nuggets. Most projection welding processes do not incorporate preheat be it aluminum or any of the steel alloys.

Reference: AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA – RWMA Resistance Welding Manual 4h Edition