Flash and butt welding both use the work piece as the electrode. They both use a clamp to hold the parts and apply force. The entire cross section of the work piece is welded. It is in the timing and application of force and current that they differ.

Flash welding uses similar clamps but the parts are placed close to each other before force is applied. Current initiates with the intent of creating an arc which generates large amounts of metal flash. This flashing action both cleans and heats the mating faces of the parts. Then force is applied and Joule H= I2rt heating begins. Power is turned off. Part cools and force is removed.

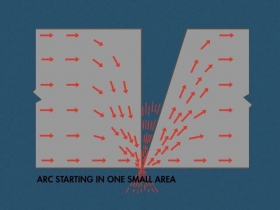

Because the parts are held close but not together under force an arc or many arcs jump across the gap between the two parts. As the arc burns the metal is expelled and the initiation point/protrusion arcs away and the surface begins to come into equilibrium until the entire surface is arcing. This cleans heats and in a sense levels the surface for bonding. Force is applied as the arcing current is removed. Upset begins to the desired amount and then the weld is cooled.

Flashing or arcing canceled out the rough cut or uneven surface of the mating part surfaces and makes flash welding more forgiving.

Reference: RWMA, Resistance Welding Manual, Section 5