There are several variables that must be considered during flash welding.

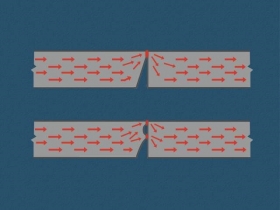

Joint Design: The part must provide for even heat on both sides of the weld. Adequate length of material must be provided to allow for flash. There must be suitable area to clamp the part. There must be room for the flash product to escape from the weld area.

Heat Balance: Two pieces of the same size and material will heat the same but if the materials differ they will not. One part will heat more and in turn flash more. The clamp location must be located to allow for this added flash material.

Surface Preparation: Normally is not an issue with flash welding.

Flashing will begin and burn until the surface clean and fully heated.

Initial Electrode Opening: This is determined by trial and error at set up. Allowance for upset and flash off plus some standoff room for the clamps must be determined.

Alignment: Alignment in the welding machine is important to keep flashing on the faying surfaces uniform. Distortion of the part can result if not aligned properly.

Gas Shielding: In some applications prevention of oxidation can help improve the joint. Argon and helium shielding gases perform well in this regard. Shielding gases do not eliminate the need for proper set up and weld procedures.

Welding Schedule: The machine control automatically runs the actual weld and machine functions. The proper parameters are developed during the set up operations. The machine and control system can repeat this accurately and produce many quality parts.

Post Heat: High alloy steels may need a post heat operation to temper their material. The control is capable of handling this as part of the weld schedule.

Flash Removal: For cosmetic reasons the flash material is frequently removed or cut back. For strength reasons leaving some of the flash fillet does increase the overall strength of the weld. It is easier to remove the flash is when it is still hot. Methods include machining, grinding, deburring wheels, oxy-fuel gas cutting, sanding, and pinch off type electrodes.

Reference: RWMA, Resistance Welding Manual, Section 5