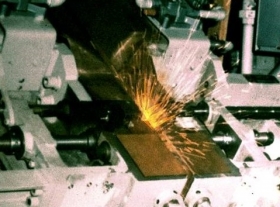

Flash welding is designed to begin the process with an electrical arc struck between the two parts to be welded. This arc will create an excessive amount of heat on the two mating surfaces where it makes contact. The result is molten material forms at the point of impact. This molten material frequently is expelled out of the joint as flash. It is hot and dangerous and shielding should be used for personal safety. This same flash can accumulate on the machine, the part and surrounding areas. Clean up will be required to maintain good safe housekeeping. Minimize magnetic materials in the area if welding to reduce steel slag accumulation.

This flash is good for the process and is necessary because it is both heating and cleaning the faying surfaces in preparation for making a good joint.

Flash being expelled during flash welding

Flash welding is an economical process because large areas can be heated with a modest amount of power as compared to other processes. It is fast and reliable.

Reference: RWMA – Resistance Welding Manual Section 5