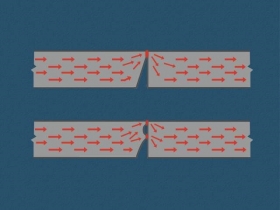

In general flash welding does not require part preparation. The two mating surfaces do not need to be cleaned. The arcing will remove the surface contaminants. The surfaces do not have to be flat to mate up well. In fact a rough cut creates arc initiation sites. If anything one might cut the material on purpose to create a rough surface or even a sloped surface. A sloped surface will concentrate the arc at the point which touches first. It will burn away quickly until the whole surface is arcing. It is the arcing action which cleans and brings the part up to the desired conditions needed for good joining.

Flash Weld Initiating on Sharp Edge or Rough Surface

It is important that force not be applied prior to the arc initiation. We do not want to make good surface contact. We want to encourage arcing initially. After arc/flash cleaning and heat buildup then force is applied. The part is upset and a joint is formed using Jules Law H=I 2rt.

Reference: RWMA – Resistance Welding Manual Section 5