There is no simple way to determine the power for a spot weld job. To determine the power requirements, one must know the approximate weld schedule. Weld schedules are dependent upon the product being welded. For every application one must know the material, thickness and any coating. What are the weld nugget specifications if any. At this point one goes to sources for weld schedules. An article in this blog covers this:

WHERE CAN I FIND WELD SCHEDULES?

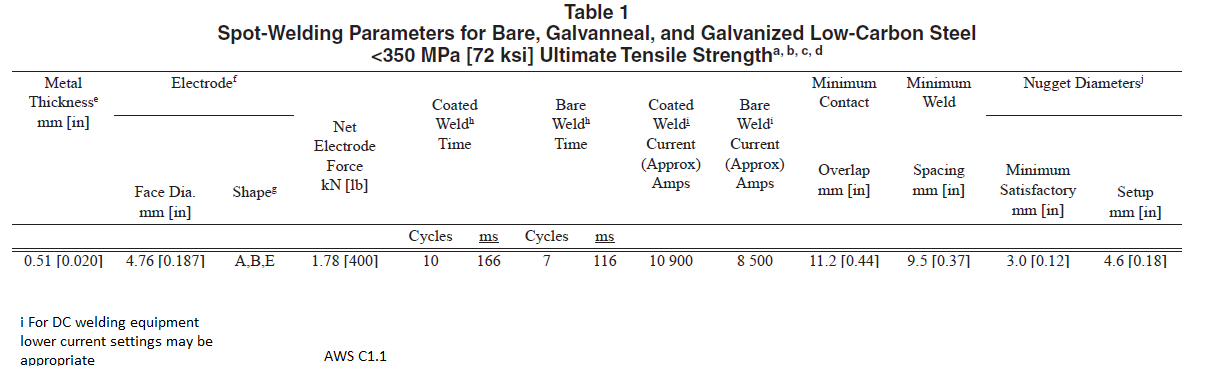

Weld schedules will provide an approximate amperage and length of time for current flow. As discussed in the above article many other critical data are provided necessary for set up including electrode selection, force and resultant weld nugget. These schedules do work.

With the amperage and time and the number of welds per minute and parts per hour one can back into the duty cycle and power. With the weld schedule and the data just mentioned you could read the article:

HOW DO YOU SIZE A RESISTANCE WELDING TRANSFORMER?

The current values and data found in the weld schedule are used here to calculate the transformer size. With the transform determined the appropriate machine can be chosen to weld the product.

One can always turn to local machine or transformer suppliers and they can help with evaluations and give guidance.

References: AWS C1.1 Recommended Practices for Resistance Welding

RWMA – RWMA Resistance Welding Manual 4th Edition

CMW Resistance Welding Products Catalog

Tuffaloy Resistance Welding Products Catalog