Weld schedules are available in the Resistance Welding Manual and AWS Standard C1.1 for many of the most frequently used materials. The information commonly provided is the proper electrode design, size and material. The weld force, weld time and weld current are also published. The minimum distance between welds is usually listed and the expected nugget or button size is shown. Tensile properties frequently are also published. Other sources widely distfributed are the Tuffaloy and CMW Catalogs.

All of this is good information to use as a starting point. Each application will dictate some variation from these settings but these numbers will act as a good guide or goal for your application.

Other sources for weld schedules can be found at AWS. AWS C1 and AWS D8 both publish other bulletins that contain data on resistance welding and testing.

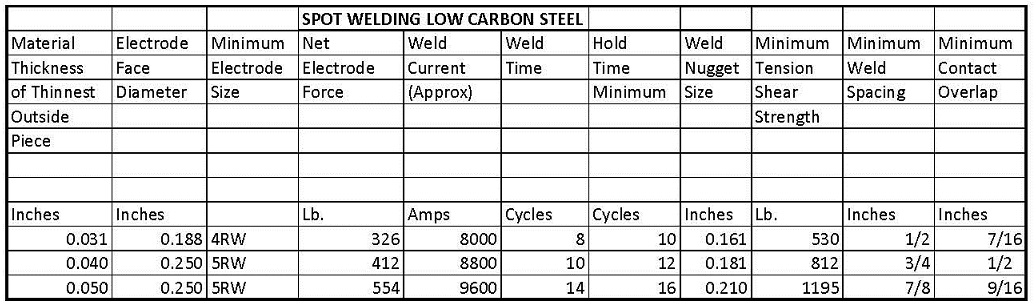

An excerted partial table (Ref CMW Inc Catalog, Page 70) is shown below to demonstrate the type of data that can be provided in the typical weld schedule.

These values are good starting points and will produce weld nuggets. They will work but your actual material, equipment and quality standards may dictate variation from these values to achieve your required results.

Since every machine and set up varies your initial trial should be at a current substantialy lower than the above in order to be cautious and prevent possible expulsion. After the first trial weld one can then safely adjust the current slowly up until heat and a weld are obtained.

Reference: RWMA - "Resistance Welding Manual 4th Edition"

AWS Standard C1.1, Recomended Practices for Resistance Welding

CMW - Resistance Welding Products Catalog

Tuffaloy - Resistance Welding Products Catalog