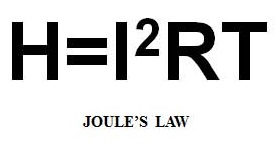

Copper because of its high conductivity is very difficult to resistance weld. Joule’s Law states:

Copper has relatively no resistance. It does not want to heat up. So very high current would be needed. The reference materials state it is impractical to weld.

Resistance brazing methods are used., the heat is generated by using high heat generating refractory metal electrodes of RWMA Class 13 or 14. They get hot and transfer heat into the copper. Zinc and tin coated copper are used as a semi braze alloy to melt and form a joint but may be limited by their low joint strength.

The most reliable option may be a true resistance braze. An intermediate true braze material is place in the braze joint and “Joule’s heating occurs there and forms a braze when it resolidifies.

These topics are discussed in more detail in the following articles:

CAN COPPER BE RESISTANCE WELDED?

HOW CAN THE WELD STRENGTH BE IMPROVED FOR RESISTANCE WELDING ZINC OR TIN COATED COPPER?

A resistance braze is probably the preferred process to bond the two pieces of 1.5 mm (0.059”) copper together.

Reference: RWMA – Resistance Welding Manual 4th Edition

Tuffaloy Products Catalog - Recommended Electrode Materials