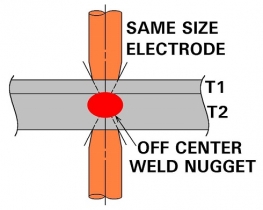

Heat balancing is adjusting heat input so that the nugget forms at the center or more importantly the faying surface. Resistance welding two different work piece materials will often cause the heat to build up in one before the other. The same is true if the thicknesses are unequal. This frequently leads to the nugget forming mostly in the hottest side of the part instead of at the faying surface.

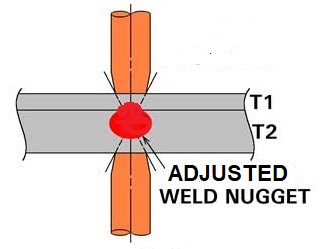

To create the heat at the faying surface we must cool down the side of the part that is too hot or heat up the side that is too cool or both. This can be done by using a larger electrode face size on the hot size. Use a “C” flat face on this side. The current and heat are spread out and the heat dissipates. The nugget will form closer to the faying surface.

The other choice is to use a colder more conductive electrode on the hot side. Change from a Class 2 to a Class 1. Conversely the opposite can be done on the cold side of the part. Smaller weld faces and hotter electrode materials. The goal is to push or draw the weld nugget toward the desired area of the part.

After adjustment the nugget has moved into the upper sheet.

Reference: RWMA - Resistance Welding Manual 4th Edition