Burnout is a term that I am not familiar with. This term implies two possible events:

• Expulsion at the electrodes

• Transformer Failure

I will look at each of these individually.

EXPULSION

This refers to expulsion of hot material from the weld face area. Numerous articles have been written on this subject in this blog:

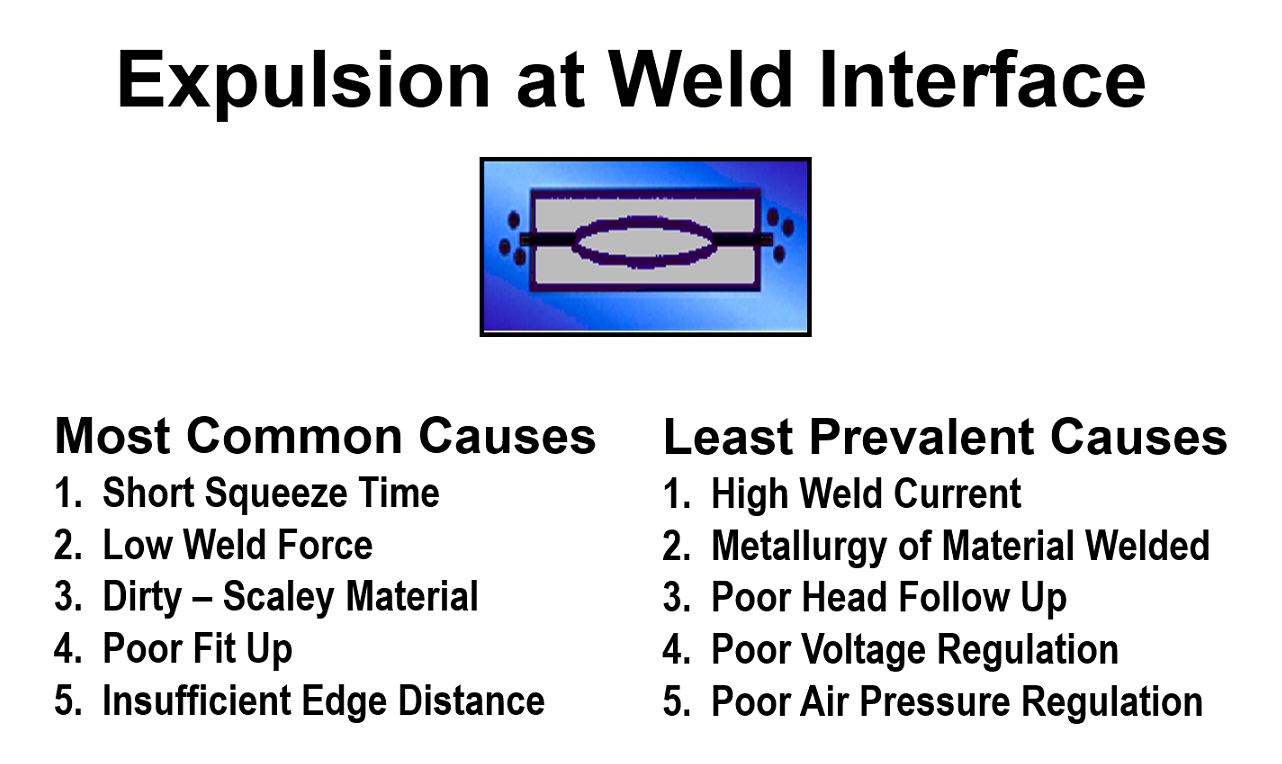

WHY DO I HAVE EXPULSION AT THE WELD INTERFACE?

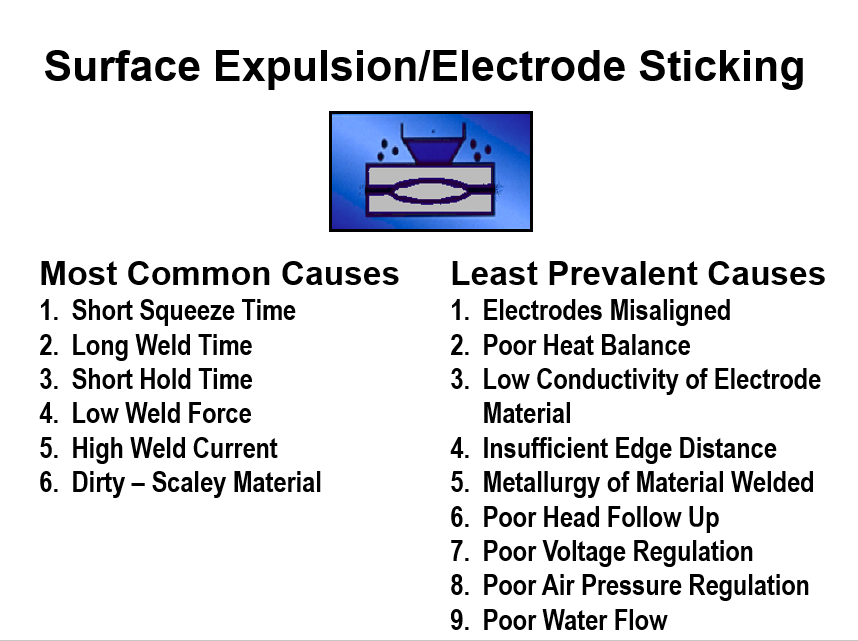

WHY DO I HAVE SURFACE EXPULSION?

Each of these articles list many reasons for expulsion. Each of those reasons has it’s own article in this blog explaining how it affects the weld and expulsion.

Do a search for the individual listed reasons and read the articles.

Expulsion leads to severe/accelerated electrode wear and is dangerous for personnel nearby. It also can coat machine parts and the product being welded with weld flash.

TRANSFORMER FAILURE

The other definition of BURNOUT could be failure of the transformer. There are only two general concerns for transformer users:

• Overheating

• Drawing more power than the rating for the transformer.

The fix for this is ensure that the transformer has the proper water flow as required by the manufacturer. Secondly confirm that the transformers are operating within the rating limits litsted on the manufacturers attached label.

Beyond this transformer issues and testing need to be addressed with the manufacturer of the equipment. Equipment design and maintenance is not in the realm of this blog.

References: RWMA – RWMA Resistance Welding Manual 4th Edition

AWS – AWS Standard J1.2 Guide to Installation and Maintenance of resistance Welding Machines