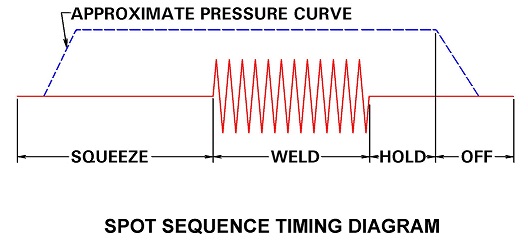

Pressure, current and time (PCT) are the basic functions performed by the resistance welder. These functions are controlled or initiated by the weld controller. It initiates each step when told to start the weld process by input from the foot switch or automation PLC. The controller allows time for each step to operate and controls the current amplitude. In simplified form this is Squeeze, Weld and Hold. The squeeze sequence allows the pressure system to build up the force to contain the weld. The weld function is the actual current flow and is totally controlled by the weld controller. It regulates the amplitude and time of current flow. Hold is the period which allows the weld nugget to cool down and solidify under force. The controller regulates this time.

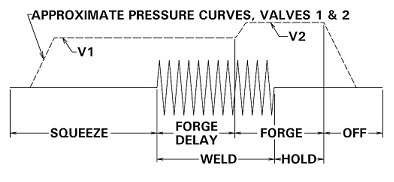

FORGE/HOLD SEQUENCE

In AC welding the time is measured in cycles. Mid frequency (MFDC) equipment measures time in milliseconds. This time measurement applies to the squeeze, weld and hold functions. The current segment is measured as % heat on many AC devices but many newer devices measure current in amperes. MFDC controllers measure in amperes.

The controller does not regulate the force on most systems. It initiates the signal to a valve or solenoid which starts the application of force by a cylinder or servo. In some cases the controller gets feedback that the force has reached a predefined value before it allows the weld current to initiate.

The function of hold is to ensure that the weld nugget solidifies under force. If the force is removed too soon voids and cracks or no weld will result.

The question above:

How does hold time change the nugget strength?

If there is no hold time the nugget may solidify with no force. The faying surfaces could separate or at the least voids could appear in the nugget leading to low weld strength. With a hold sequence the faying surfaces cannot separate. The nugget cools properly and most or all voids are forged shut by the applied force.

An overlooked function of resistance welding is the work in a blacksmith shop. Every piece of metal had to be forged to be strong. In resistance welding part of this forging is the hold operation. Hold strengthens the weld with a standard hold or in some cases an increase forging force as shown above. The applications of extra forging force is applied as shown above to accentuate this process.

If you are currently welding with very short or no hold times, adding hold time could conceivably increase your weld nugget strengths. This does not necessarily increase the nugget size it increases the strength of the nugget by closing voids and forging the nugget.

Reference: RWMA - Resistance Welding Manual 4th Edition