A dent free spot weld can be defined as a “Cosmetic Weld”. This is a spot weld where one side of the weld would show little or no electrode indentation. The middle of an automobile hood would be a location where an indentation would not be desired. Medical instruments are another example. By the nature of the resistance welding process metal fusion and indentation are inherent features of the process. Control of the amount of heat and where it is applied is the path to producing a cosmetic weld.

The goal is to keep one side clean and flat.

• Start with a flat faced RWMA “C” nose electrode on that side of the part. It will keep it cool and tend not to indent.

• On the other side use a much smaller faced electrode to concentrate the heat in a small area.

• Make sure the non-flat side is the hottest side. You may want to use a less conductive electrode material on this side.

• Minimize the total size of the weld nugget

• Keep the nugget concentrated in the back up sheet away from the face sheet.

Remember the goal is to drive the heat in from the back side. Form the bulk of the nugget on the back side. Grow the nugget just enough to – just reach the second/front sheet and stop/cool down.

• There is no written process to attain a COSMETIC WELD.

• It is trial and error.

• Cosmetic welds are difficult to attain and maintain.

• They exist in a very thin realm between “ACCEPTABLE INDENTATION and NO WELD”.

COSMETIC WELD

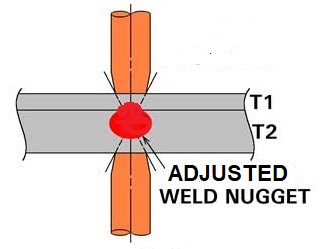

Sketch of cosmetic electrode part set up showing weld nugget to one side and indentation on one side. This sketch does not illustrate the suggested differences in face size.

Another Article in this blog:

Reference: RWMA – Resistance Welding Manual 4th Edition