Seam welding can involve large amount of power especially in a continuous seam weld. This generates a lot of heat which must be removed. The weld wheels are cooled through the hub that attaches them to the machine. Unfortunately this can be a long distance from the actual weld face. Just as in spot welding we need cooling near the face to help maintain the wheel integrity. In higher heat applications external water may be required. Water tubes are installed on both sides of the wheel top and bottom and cool water is spray on the wheel and weld area. This of course can be very messy but necessary for some applications.

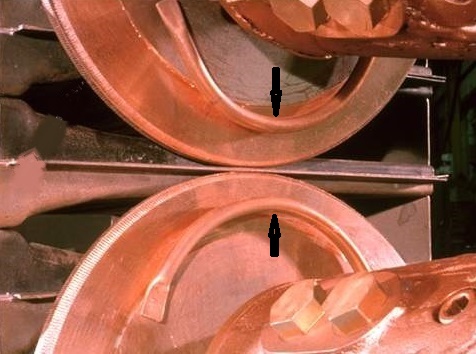

Wheels with curved copper water lines for cooling

Reference: RWMA - Resistance Welding Manual