Cracks appearing in the parent material around the weld nugget can be caused by several issues. They are:

High Weld Force – can fracture the parent material with excessive forging action.

Insufficient Cooling – Over heating can cause excessive stresses from expansion and contraction along with the forging action.

Metallurgy of Material Welded – Some materials become brittle at the temperatures experienced in resistance welding.

Other factors that could cause fractures are small electrode face areas and short hold times.

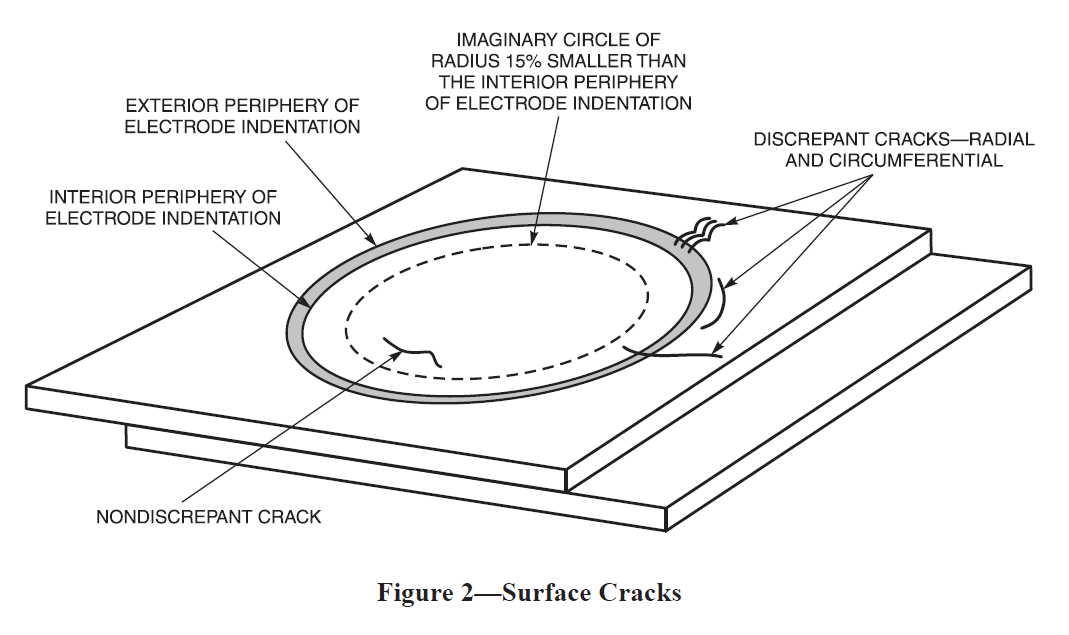

A sketch of surface cracks is illistrated in AWS D8.1 Figure 2 shown here:

References: CMW Welding Products Catalog

RWMA - Resistance Welding Manual 4th Edtion