Resistance welding transformers are very robust. They can operate for years without any problems. When they fail it is catastrophic. A short between the primary and secondary coils is one method of failure. This occurs when the insulation between these coils fails. It is a very thin separation between the primary and secondary coils. Any damage to this thin layer can lead to a catastrophic short between the two coils. To prevent this from happening on the replacement transformer the cause for the short must be sought and a plan to prevent in the future put into place.

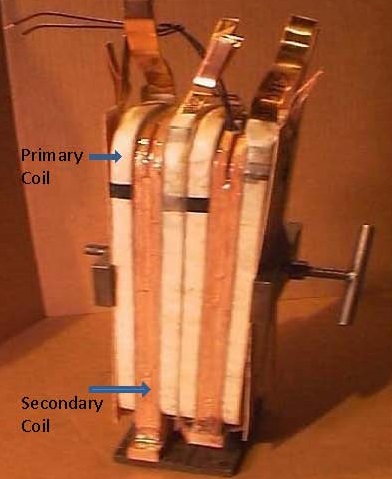

Transformer Coils Assembled showing primary and secondary coils. Simpolified Sketch of The Power Components

Many factors must be evaluated to find the root cause for the failure. Some of the factors that should be looked at are:

IS THIS A NEW MACHINE AND NEW INSTALLATION?

With a new machine in a new installation, the installation and how the machine is being used must be evaluated.

Were all components installed properly? Were the leads to the transformer installed as specified by the manufacturer? Three phase DC power is supplied in a “Delta” or “Y” configuration. Was this maintained as required for the primary connections? Is the transformer rated for the input voltage connected?

Is the water cooling hooked up with the proper rate of flow, temperature and quality for the transformer? Was the water on and flowing when the power was initiated? Operating the transformer without proper cooling will lead to heat buildup and possible insulation failure. When the insulation between the primary and secondary coils fail the two can come into contact and you have an electrical short. The fuse or circuit breaker should trip (If there a proper electrical ground on the machine) (including the negative pad of the transformers, the transformer casing, the machine and the weld control). If shorted the transformer is ready for removal and possible repair. Was the water on for a period of time that the machine was not operated? This could lead to condensation in the transformer if the primary and secondary windings are not sealed and protected from moisture. Transformer condensation could result in a failure.

Are there flow indicators on the exit side of all transformers? You must be sure there is proper water flow.

IS THIS A NEW MACHINE THAT HAS OPERATED SUCCESFULLY FOR A WHILE?

If the machine is relatively new, but has run well for a while then the installation as noted above, should be double checked before turning to other factors. Water flow and temperature must be checked. Are there flow indicators on the exit side of all transformers? Has the water quality been maintained properly (conductivity, ph, and total dissolved solids)? Has the water been left on during periods the machine was not being used such as between shifts or over a weekend? If water is left on for long periods without operating and the primary and secondary windings are not sealed and protected from moisture, condensation could form inside the transformer. The condensation can lead to insulation failure and an electrical short. If the water is normally turned off during idle periods, was it turned back on when the machine was fired up again?

IS THIS A USED MACHINE THAT WAS RECENTLY SET UP IN A NEW INSTALLATION?

A used functioning machine may indicate the transformer is not a suspect as the cause. However in any new installation physical damage to the transformer from the move to the new site could be an indication of a potential failure source. Is the transformer rated for new voltage and power? To test a new used transformer for integrity before installation, the insulation must be tested. Common test are Hi-Pot and Megger. These can be performed by transformer or other electrical test facilities. If the transformer is good, then attention must turn to the electrical installation of the transformer as mentioned above. The water flow and temperature must be double checked. Are there flow indicators on the exit side of all transformers? Has the water quality been maintained properly (conductivity, ph, and total dissolved solids)?

IS THIS A USED MACHINE THAT HAS BEEN WELDING SUCCESFULLY?

If the machine has been running for a long time without a problem, then one should look for a change in the normal operating procedures. Water flow, temperature and quality are candidates to investigate. Are there flow indicators on the exit side of all transformers? Has the water quality been maintained properly (conductivity, ph, and total dissolved solids)? When is the water turned off or on relative to inactive periods of the machine? When the machine is off the water should be off. When the machine goes back into use the water must be turned back on before welding.

IS THE CONTROL INSTALLED PROPERLY AND FUNCTIONING?

The control must have the proper over current protection and be sized properly for the load. It also has a cooling requirement for the SCR’s that can break down if overheated. Water flow, temperature and quality must be checked. Are there water flow indicators on the exit side of the control? Has the water quality been maintained properly (conductivity, ph, and total dissolved solids)? SCR’s should be tested to see if one or both have failed. When an SCR fails, it fails in the “ON” state and will pass full primary current. This full current could damage the transformer if it overheats. The transformer may have overheated and damaged the thin insulation between the primary and secondary. This results in an electrical short and a failed transformer.

Reference: RWMA Resistance Welding Manual, Sections - 19 & 25

Roman Manufacturing Inc.