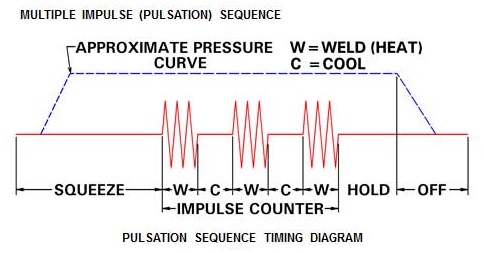

Weld pulses are frequently used to grow the size of weld nuggets without overheating the part. In most cases the pulses are a repeat of the initial weld sequence with a very short one or two cycle cool between sequences. The diagram below depicts this type of sequence.

One could also make a series of pulses by programming (chaining) a series of weld schedules to sequence one after the other. Then the power could increase or decrease based on the selected weld schedules and the circumstantial need. Upslope, weld and downslope might be considered a pulse because this combination extends the weld time to improve the weld condition.

Most controls can pulse the initial weld sequence or chain a series of weld programs together as desired. Circumstances will dictate the best choice.

The number of weld sequences can be repeated as desired with a brief cool in between each. When done the weld sequence ends with the normal hold and off to cool down the weld under pressure and end the process. This process can be called impulse or pulsation depending on the control being used.

Reference: RWMA- Resistance Welding Manual 4th Edition