In resistance welding there are three main functions performed during the weld operation. They are pressure application, and current flow for a length of time “PCT”. All of these functions are initiated, controlled or monitored by the weld control. The weld current amplitude and time are controlled by the weld control. The weld time in an AC control is measured in cycles. There are 60 cycles/second in North America. Most resistance welds are 5 – 30 cycles long making them very fast at less than a second long.

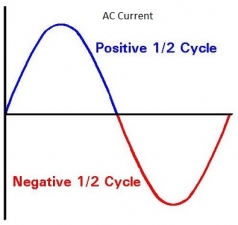

This is a typical single AC sine wave. One cycle is made up of two half cycles, a positive half and a negative half. This repeats 60 times/second in AC current. The weld control accurately counts these cycles to deliver the same number or cycles each and every weld. This is the weld time that current flows through the part being welded.

In MFDC or mid frequency welding the weld time is measured in milliseconds – see ”What is MFDC Weld Time?”

Reference: RWMA Resistance Welding Manual

ENTRON Controls LLC