Resistance welding transformers are manufactured with very little space between windings and between the primary and secondary coils. To provide electrical integrity they must be separated by insulation. This must be maintained throughout the life of the transformer. This insulation is very thin but can last for a very long time if not abused by heat, moisture or physical damage.

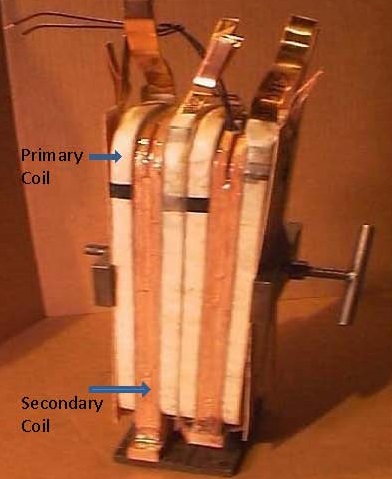

TRANSFORMER COILS ASSEMBLED SHOWING PRIMARY & SECONDARY COILS

As transformers age or a machine is being recommissioned the condition of the transformer should be considered. Is it in good shape and ready for another long model run? The question can be evaluated and tested. A transformer manufacturer has the proper test equipment to do this and can evaluate and potentially repair, if necessary.

If one is considering evaluating a transformer in house then the following path would be suggested:

Resistance welding transformers require integrity of the insulation between windings in order to operate correctly. The resistance value of the insulation cannot be measured with a typical multi-meter. It must be tested with a Megohmmeter. When resistance welding transformers are new the insulation resistance between primary and secondary winding, between primary winding and case, and between secondary winding and case will typically be greater than 500 MΩ. In fact, many Megohmmeters will show readings of infinity when testing new transformers. As transformers age and are exposed to typical contaminants found in factories (water, weld flash, hydraulic fluids, etc.) the insulation resistance degrades.

When evaluating a transformer to be reinstalled or for continued service the insulation resistance should be measured. You should consider replacing a transformer if any of the insulation resistance readings are found below 50 MΩ. However, it is always best to contact the transformer manufacturer to determine the minimum insulation resistance at which a transformer should be left in service.

Reference: RWMA Resistance Welding Manual Sections - 19 & 25

AWS Standard J1.3 Guide to Installation and Maintenance of Resistance Welding Machines