This answer to this question is included in the answer of another article:

HOW DO YOU SIZE THE PRIMARY CONDUCTORS FOR AN AC RESISTANCE WELDING TRANSFORMER?

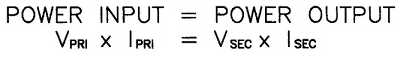

It builds upon the formula:

In this instance we have a 250 KVA AC machine transformer with a high tap of 25.8 volts and a low tap of 12.9 volts.

All of this depends upon not overheating the transformer Therefore we must operate at no more than 50% duty cycle. The above article explains how to insure the transformer is operated under safe conditions:

If the Duty Cycle or Weld Current are not known or this is a general purpose machine:

1. Divide the transformer nameplate KVA by the primary voltage.

2. Multiply that result by the square root of 0.5 (RWMA transformers normally are rated at 50% Duty Cycle)

3. The result is the Primary Effective Continuous Thermal Current (ECTC).

4. Refer to the Ampacity Chart of the cable type to be used. Select the size based on the Primary Effective Continuous Thermal Current (ECTC).

Ampacity charts are based on the National Electric Code (NEC). There may be other state, local or company standards that must be followed.

Reference: National Electric Code

RWMA Manual Chapter -21.7

Roman Manufacturing Inc.