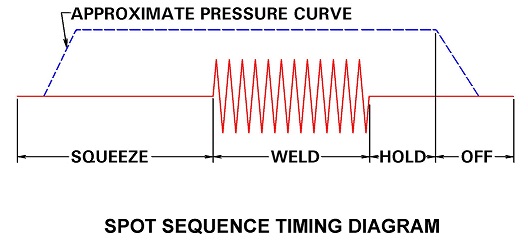

The weld control manages many functions. Its main function is to initiate or control the functions of pressure, current and time. It initiates the start of the weld sequence at the desired time by closing the electrodes and initiating the force/pressure buildup. At the desired time it turns on the current at the proper level for the desired time and then turns it off. The pressure is maintained until the part has cooled and then pressure is removed. The squeeze, weld, hold, off sequence is complete and the control is ready for another weld sequence.

This is the traditional simple process. There are many variations or additions to this process. To name a few, up slope, down slope, forge, temper, pulse, current steppers, adaptive controls and many more.