For many years AC was the system of choice for resistance welding. DC was present for those applications that demanded high power where balanced three phase input and large secondary outputs were necessary.

Over the last twenty years MFDC (mid frequency direct current) offered a means to lighten the weight of the transformer which made robotic welding a practical resistance welding application.

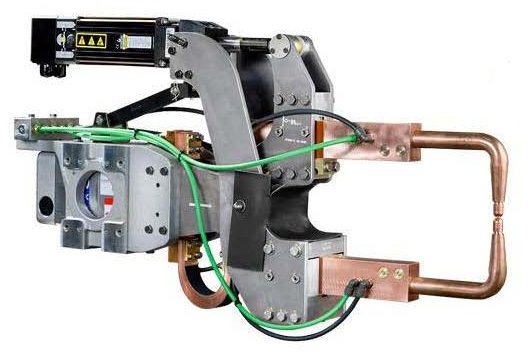

Transgun with MFDC Transformer and Servo Actuator

Today MFDC is the largest application of resistance welding transformers. It has found wide acceptance in all industries. It is a balanced three phase, can use less power and has a power factor near unity.

The power factor comparison is:

AC – 0.3-0.8 (Varies with throat configuration)

MFDC- 0.99

Reference: Roman Manufacturing - White Paper 2017 “A Comparison of AC to Inverter DC Resistance Spot Welding and the Effects On Dual-Phase 600”