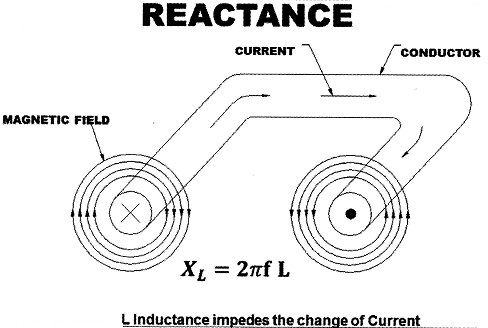

Reactance is created by the induced magnetic field around the conductors.

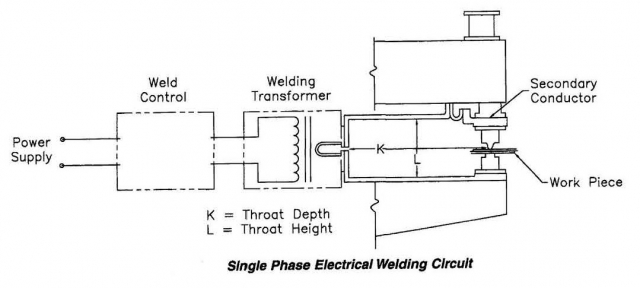

This induced field wants to stay in a steady state but in AC, current is constantly changing from positive to negative with the AC sine wave. The Reactance builds momentum in each half cycle and resists changing to the other direction. The stronger the magnetic field the larger the reactance (resistance). The size of the welder throat is a factor in determining this magnetic strength. Larger throat areas create stronger magnetic fields.

Larger K & L lead to increased reactance

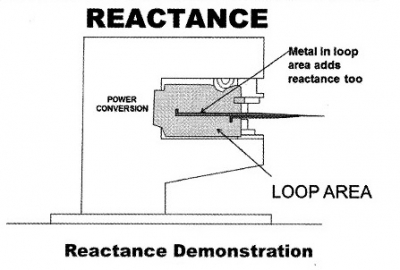

Additionally magnetic material in the form of tooling or the workpiece itself in the throat adds to the reactance and reduces the current flow.

Magnetic tooling or the workpiece will absorb energy In the throat of an AC Resistance Welder

The issue created by reactance is that the equipment may have to run at higher operating levels than otherwise required. In many cases this can still be well within the capabilities of the machine. In other circumstances one could overdrive various electrical components which could lead to premature failure.

To optimize current flow minimize the throat size. Whenever possible, run insulated conductors and cables close together.

This is an issue for AC equipment. DC and MFDC do not have any reactance or magnetic material issues.

Reference: RWMA Resistance Welding Manual Revised 4th Ed Chapter 19

Roman Manufacturing Inc.