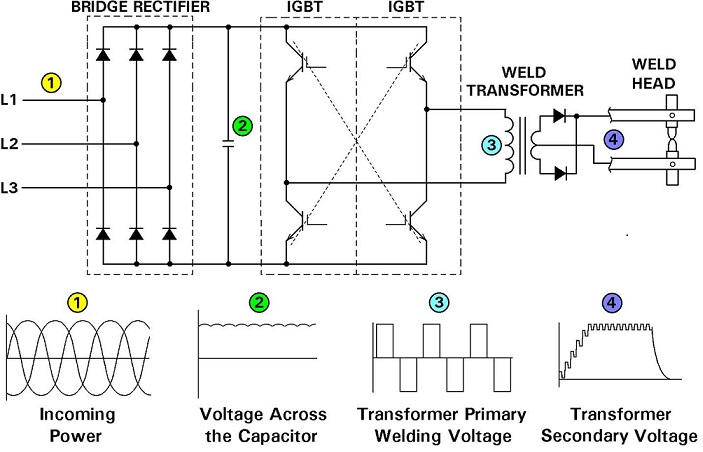

MFDC stands for MID FREQUENCY DIRECT CURRENT. This is a control and power supply system that takes an AC power input and converts it into an inverted higher frequency power output. Three phase AC @ 60 hertz goes in. It is inverted and converted a combination of times in the control and transformer to end up with a 400 – 4000 hertz inverted DC output.

Schematic Power Conversion In Control and Transformer of Mid Frequency Inverter

The weld current has no zero cross overs which would cool the part. Therefore the part heats quickly. It is DC so there are no inductive power losses or problems with magnetic material in the machine throat.

Generally the plant power requirement is reduced substantially. Transformers can be reduced in size allowing better payloads for robot applications. Welds are fast, in a few milliseconds.

A related article is:

WHAT ARE THE FUNCTIONS OF AN MFDC TRANSFORMER?

Reference: ENTRON Controls LLC

RWMA - Resistance Welding Manual 4th Edition