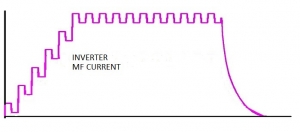

In mid frequency (MFDC) resistance welding the AC current is transformed from 60 cycles/second (hertz) to 400-4000 hertz and the negative half cycle is inverted to positive creating a DC current. The current does not have zero cross overs therefore it is conducting power continuously and can heat the part much faster than traditional AC welding. The weld control which controls this current amplitude and weld time must be very responsive to maintain control. It measures time in milliseconds. There are 16.66 milliseconds per each AC cycle. This is equivalent to 1000 milliseconds per 60 AC cycles. Welds are made at less than 10 milliseconds and up. They can also be run at modestly longer times and reduce the current level to compensate.

In AC welding the weld time is measured in cycles – see ”What is AC Weld Time?”

Reference: ENTRON Controls LLC