In many manufacturing facilities the power in the plant is not sufficient to maintain constant power throughout the workday. A resistance weld schedule can be developed and during the course of the day the operators notice that by mid-morning their welds are getting smaller. They need more power. Then when second shift comes in they have too much power and have to turn it back again. In some cases this can be traced back to a lack of power in the plant and a voltage drop due to the large usage during the main productive hours of the plant.

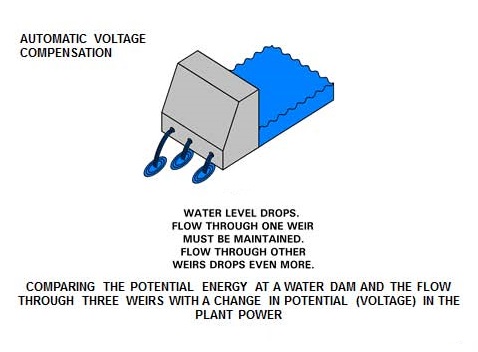

Controls can be designed to compensate for this situation with a constant voltage feature. They will maintain a constant voltage to the welder no matter the input voltage. This will level out the variation during the day and make production more efficient. The figure below compares the water from a dam with varying water level to the possible voltage change in a plant. This demonstrates the need for voltage compensation in some facilities.

Reference: RWMA - Resistance Welding Manual 4th Edition