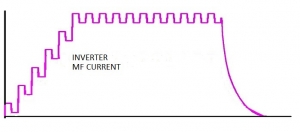

An inverter weld control is one in which the AC positive and negative half cycles have been inverted. The result is all half cycles are positive and their frequency is increased. They generally operate at 400 – 4000 cycles per second.

Because the current never crosses zero there is no cooling during this current flow. Heating is much faster and there is more power in less time and less current input. It is a DC weld therefor magnetic affects are not as much of a problem. This means that throat depths and magnetic materials in the throat are not much of a problem.

Reference: RWMA - Resistance Welding Manual 4th Edition