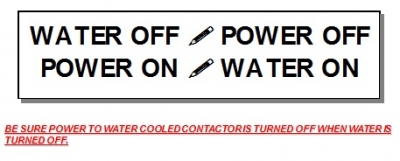

The general rule of thumb is to turn the water off when you turn the power off and in turn the water should be turned back on when the machine is powered up again.

See Article: “When Should the Cooling Water be Turned On?”

If the chiller remains on during a machine off period, it may be fine provided that there are no water leaks and condensation does not accumulate anywhere on the machine. This can be critical in the SCR, the electronics of the controls and the transformer. Condensation on or in any of these components can lead to a short and failure of the SCR, Transformer or Control.

So the question might be how cold is the chilled water? What is the ambient humidity? How long will the machine be idle? Are there hose leaks that normally are dried up by the equipment operation? If any of these answers would indicate water accumulation then shut the chiller down and protect the equipment.

If the water was left on during the down time and water did not accumulate on any surfaces today the gamble paid off and you should be able to turn the machine back on and operate again.

Remember the recommended method to protect the SCR’s, Control and Transformers is:

References: AWS Standard J1.2M/J1.2:2016 "Guide to Installation and Maintenance of Resistance Welding Machines"

RWMA Manual Fourth Edition