Current monitors usually allow one to set high and low limits around the desired set current. These can be used as an alert that the process is changing and action might be necessary to maintain good weld quality.

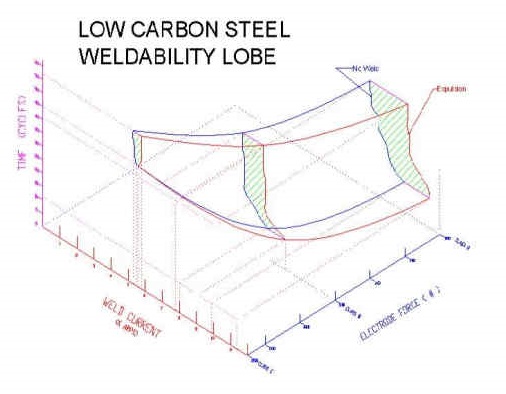

Selection of the initial desired set point is determined by the desired quality and the general philosophy of the manufacturing facility. Some facilities prefer to operate near expulsion and others prefer to run midrange in the weld window.

Any point inside the weld window/lobe should produce a good weld. If one chooses to operate on an extreme near expulsion there is little room for error. The alarm would be set very tight? If the current raises on the top side expulsion and overheated burned product could be expected.

Conversely if one operates on the low end. One is risking producing small or a “NO WELD” situation. One never wants to be at the low end and produce small or no welds. Current must exceed this.

The answer is the choice of the operating current setting and any monitor setting alerts around this setting are determined by the individual plant their individual need to meet the manufacturing requirements.

This is beyond the scope of this blog.

Another related article on this subject is:

WHEN SHOULD A WELD MONITOR BE SET UP TO SAMPLE DATA DURING RESISTANCE WELDING?

Reference: RWMA – Resistance Welding Manual 4th Edition