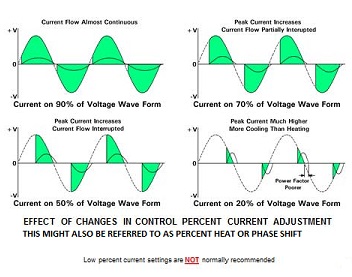

For AC welding it is important to operate at a relatively high percent heat. This gives you the maximum efficiency and minimum off time during each weld cycle of the sine wave. So your weld schedule should be designed to optimize this situation as opposed to a high tap and a low setting where a large percentage of the time (each cycle) there is no current flow and the weld is actually cooling down.

The Tap Setting Rule of Thumb is:

The affect on the phase shift is shown below:

These four graphs demonstrate why a high % heat is desired for welding. One can see that as the "current on time" is shortened there is too much off time and the part cools dramatically during each weld cycle. This is the reason for the "Rule of Thumb".

There is no single tap setting for a 200 kva transformer. Every job requirement is different and must be individually evaluated.

Set the job up and begin testing. To find the proper tap setting start on tap 1 and a low power setting and try to make a weld. Observe the results. If there was insufficient heat turn up the current or heat a modest amount each trial until you get results or your exhaust tap 1.

Then turn the power off and change to tap 2 and repeat again starting at a low current or heat setting and work up again until the desired results are achieved. Or go up another tap and repeat until good results are attained.

Remember the goal is to weld with the lowest tap at the highest Phase shift as shown above.

Reference: RWMA Resistance Welding Manual, 4th Edition