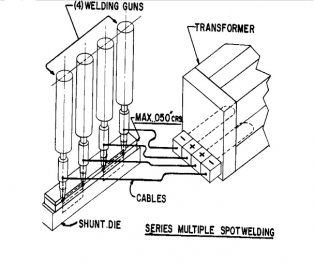

Series welds do have shunting currents as shown in the sketch below. The transformer is attached to weld guns both on the same side of the part and the current must flow through the shunting die or part to return to the transformer. Some amount of current will flow across the top sheet unless this distance is large which would increase the resistance and retard this flow. Any current flow in the top sheet is wasted current "shunting current" that does not contribute to the weld nugget. This type of tooling arrangement is used when access to the underside of the part is restricted.

Shunting in the top sheet is expected in this arrangement and is allowed for in the set up as extra current flow for each weld. The current that flows through one weld must in turn flow through the second weld to return to the transformer no matter which path it takes in the lower side of the part and backup shunt die.

Related Article: “IS THERE A MINIMUM SPACING BETWEEN SPOT WELDS?”

“IS CROSS WIRE WELDING A SERIES WELD?”

Reference: RWMA Manual- Fourth Edition, 19