During the resistance welding process the electrode face is subjected to extreme temperatures for short periods of time. To prevent premature wear, water cooling is necessary for the resistance welding electrodes. The technical term for this wear and resultant deformation is annealing. In the case of spot welding the face will begin to take on the shape of a mushroom. As this face grows the weld quality suffers and eventually weld quality failure occurs. Prevention or retarding this mushrooming is very important. One of the most important items to control is the time at temperature that the electrode weld face sees. One method of control is by cooling the electrode. The second benefit of this is that it will also cool and solidify the weld nugget during the hold period of the weld cycle.

Some questions that come to mind are:

- How close should the water tube be located?

- How much water flow do I need?

- How cold should the water be?

- Can the electrode water be run in series?

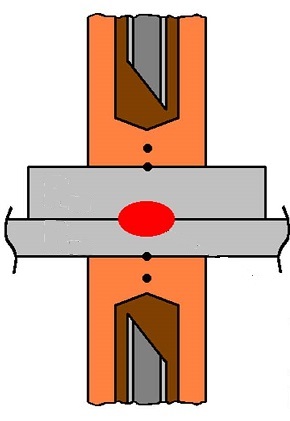

To water cool the resistance welding electrodes you should provide each electrode with it’s own internal water cooling tube located very close to the inside of the electrode weld face. For seam welding, flood cooling is used on the part and electrode/wheel right at the point where the wheel contacts the work piece. The water is usually used top and bottom and on both sides of the seam welding wheel. Projection welding electrodes are also cooled as close to the weld face as design will permit.

Properly located water tubes at inside weld face

In the case of spot welding the recommended amount of water flow at each electrode is 1.5 gallons per minute. You can weld with 1 or even 0.5 gallons/minute but electrode wear will be noticeably higher.

The water temperature for cooling the electrodes can be very cold. The electrodes can use ground water temperature in the 50’s deg Fahrenheit range. Recirculating cooling towers usually produce temperatures much warmer than this - 80 degree or higher. The electrode will do fine with the water in the 80 degree area but would be better if colder. Remember that the electrical/electronic equipment in the resistance welding system cannot handle cold water temperatures that might cause condensation on the electrical components.

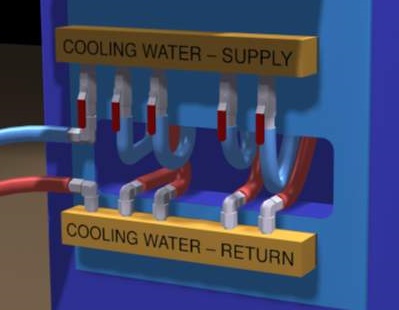

Since we are trying to make sure that each electrode gets the coldest water at the greatest flow do not run the water in series through you upper and lower electrodes or use the same water that has already cooled other components on the resistance welder. Make sure you always connect each electrode directly to the water input manifold. You should always measure water flow on the outbound side and use an in line flow meter if this is a closed loop water system.

Water Supply Manifold

References: RWMA - Resistance Welding Manual 4th Edition