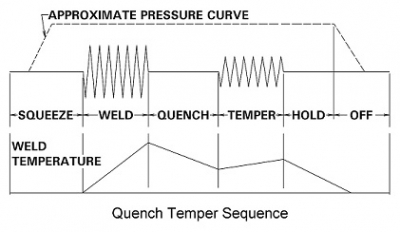

During welding operations some high alloy materials become brittle in the area near the nugget due to the cooling rate. The parts in fact are quenched in this area and are brittle. Tempering will alleviate this quenched condition. This means bring the material back up to a modest tempering temperature and hold briefly and then cool slowly.

After tempering the material structure will be changed to a moderate strong but flexible product and the brittleness should be gone.

Reference: RWMA - Resistance Welding Manual 4th Edition