The direct hot-pressing technique of powder materials is referred to as field assisted sintering. In this case resistance heating through the green pressed graphite part would generate the heat. The combination of heat and pressure would generate the desired final properties in the finished graphite product.

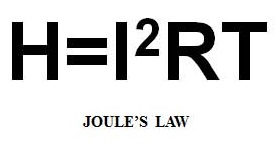

The heat is generated per Joules Law:

Yes, MFDC can be used to generate the heat for hot pressing.

It is not known if MFDC is used to heat graphite. MFDC is being used in other furnace heating applications. It is used as heating elements and is heating large ten-foot-long truck coil springs. The on time varies from seconds to minutes and hours, depending upon the application.

A search of the web found DC being used for this type of application. With proper sizing MFDC can be substituted for DC.

MFDC requires a power supply that can deliver the current / voltage to the load.

The proper sizing of this current and voltage is very important. In order to size the transformer and equipment properly an equipment supplier or integrator will want to know:

• How far is the load from the transformer?

• How wide and long are the conductors delivering the power?

• What is the cross section of the conductors?

• What is the heating element being used? (Metal being heated). This implies the fact that you can heat an element that radiates heat…. Transfer the heat to the processed material as needed.

• How much voltage and current is delivered at the load?

• For how long? (Duty Cycle, Parts/minute/ cycles/hour)

These and other questions will help the integrator / supplier design the proper transformer control package for the job.

In a heating application the equipment could be running nearly continuously. In the design of the equipment cooling the equipment is very important to ensure there is no overheating.

Reference: RWMA - Resistance Welding Manual 4th Edition