Aluminum welds have a narrow plastic range and a very high thermal expansion and contraction. This combination may be the cause for voids in the resultant weld nugget. Application of an increased secondary force near the end of the weld cycle is commonly used to forge the part in its plastic state and close these voids.

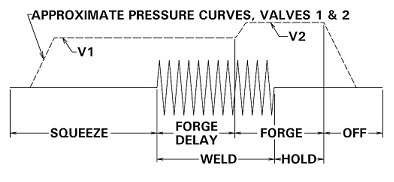

Weld sequence with forge operation.

Timing is critical in order that this does not occur too soon and retard nugget growth or too late after the nugget has formed and the plastic state has passed.

Reference: RWMA Resistance Welding Manual 4th Edition