Controls & Transformers

Questions and Answers

The answer to this question allows sizing conductors for the machine and the primary buss feed to the machine and transformer. The actual amperage out of an AC transformer depends upon the secondary itself. That will not be addressed here. Here we will address input for a given amperage output.

The first is called KVA Demand. The second consideration is Primary Effective Continuous Thermal Current (ECTC).

These topics are covered fully in two other articles:

HOW DO YOU SIZE THE PRIMARY CONDUCTORS FOR AN AC RESISTANCE WELDING TRANSFORMER?

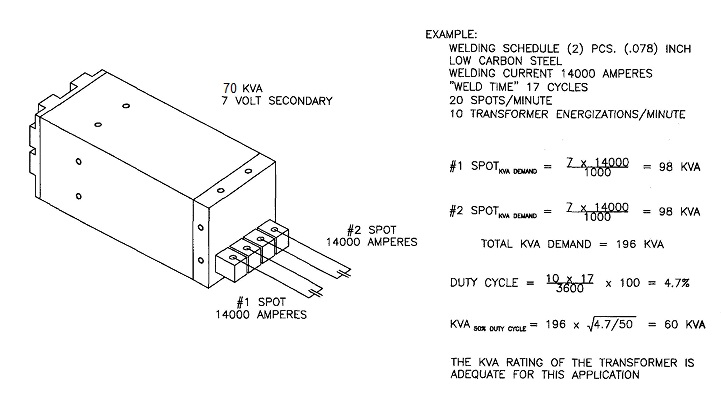

The instantaneous KVA Demand is 196 KVA

The KVA Demand@ 50% Duty Cycle is 60 KVA

The transform is rated at 70 KVA and is adequate for this job.

Apply the above calculations to your situation with 64 KVA and calculate the primary conductor size for the finalized information.

Reference: RWMA Resistance Welding Manual 4th Edition

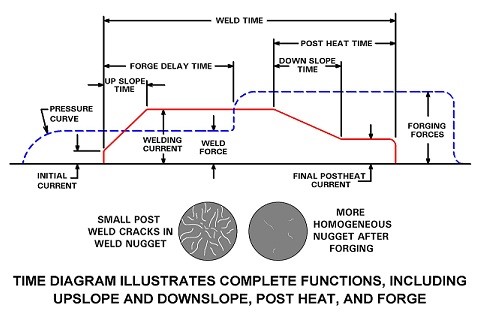

Upslope and downslope describe segments of the weld cycle where the weld current is either gradually increasing or decreasing. In upslope the weld current gradually increases from a low level to some higher current value. It might be to allow all components to warm up and reform, come together into full contact, before the full current is applied, to reduce expulsion. Downslope is the opposite. It is a gradual decrease from full welding current. This might be to prevent quenching of steel or other heat sensitive material.

Follow the links below for additional data available in this blog:

What is Upslope in Resistance Welding?

What is Downslope in Resistance Welding?

Reference: RWMA - Resistance Welding Manual 4th Edition

Insulation testing on a transformer is commonly referred to as Meggar testing. The transformer must be disconnected. An insulation tester (Meggar) must be used. The voltage is selected (typically 500V) and the Test button is pressed until the insulation resistance is displayed.

The cooling water should be blown out of the cooling lines as the presence of water may show lower values.

Three tests must be performed:

Primary – Secondary

Primary – case

Secondary – case

A tested 650 kVA transformer produced the following values:

Primary – Secondary 300 MOhm

Primary – case 300 MOhm

Secondary – case 5 MOhm

It is not uncommon for the "Secondary – Case" to read lower than the other two.

Depending on who you ask, the lowest acceptable value is 5 or 10 MOhm.

TYPICAL MEGGAR

This type of testing should be performed by personnel trained to test transformers. Transformer manufactures can perform this test.

Reference: RWMA Resistance Welding Manual 4th Edition

This sounds like the transformer insulation may be failing. This could be very serious. The primary of the transformer is separated from the housing and the secondary by what can be a thin layer of insulation. If it fails there is a direct short of primary to the case or the secondary. Either is very serious and can be dangerous.

The transformer should be thoroughly tested immediately and repaired. To be safe reconfirm the proper grounding of the machine to insure personnel safety.

Standard transformers in North America are built to the RWMA standard which calls for a 50% duty cycle rating. Based on this a series of steps must be followed, estimated or assumed:

• The primary voltage has to be a known starting point?

• What secondary weld current is required?

• What is the impedance of the circuit? This is a machine function.

• The secondary voltage will be a function of Ohm”s Law of the weld current and impedance.

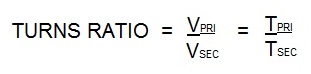

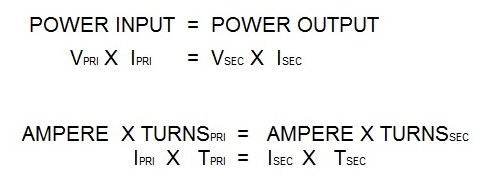

If one knows the starting primary voltage and calculates the duty cycle and knows the secondary current and can calculate the secondary voltage and turns ratio.

The answer to the original question is:

Know the primary power input.

Know the secondary welds per minute and secondary amperage.

The transformer builder can then determine the product best suited for your application.

Other related articles in this blog are:

WHAT IS THE TURNS RATIO FOR A SPOT WELDER

WHAT IS TRANSFORMER % DUTY CYCLE?

Reference: RWMA Resistance Welding Manual 4th Edition

Page 7 of 39

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.