Butt Welding

Questions and Answers

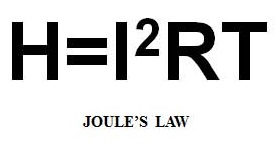

Yes, two sheets of metal can be butted together and butt welded. Butt welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. The parts are clamped and brought together with force and a current is applied. The intention is to create heat using Joules Law H= I2rt at the joint surface with current flow. As the joint heats up the force upsets the joint and a bulged area is formed. The current is stopped. The weld area cools under force and then the force is removed and the butt weld is complete. The limit to part size is the power and ability to clamp the part.

So two sheets of metal can be butted together or one sheet as shown on the example below can be formed into a ring and brought together to form the joint. The limits are power and the ability to hold the product and deliver the force evenly. If the machine is large enough with sufficient power you are making product. The example below illustrates a good example of a long butt joint being formed in one operation of the machine.

Butt welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. The parts are clamped and brought together with force and a current is applied. The intention is to create heat using Joules Law H= I2rt at the joint surface with current flow. As the joint heats up the force upsets the joint and a bulged area is formed. The current is stopped. The weld area cools under force and then the force is removed and the butt weld is complete.

A frequently used process for butt welding is welding metal rod ends together in a metal rod or wire mill. As each butt weld is made the resultant flash or upset material is mechanically removed for ease of drawing through the draw die. Multiple rod ends are welded end to end and then drawn through a draw die to size the rod to a slightly smaller size. It is frequently coiled on a coiler as it is drawn. When the desired numbers of rods have been welded together, the resultant coil is then drawn through a series of smaller dies until it is at the desired finish size. This is how rod is turned into a coil of wire. The welds are fast reliable and repeatable. The butt welds are virtually indiscernible.

Butt welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. After the parts are clamped and brought together with force a current is applied. The intention is to create heat using Joules Law H= I2rt at the joint surface with current flow. As the joint heats up the force upsets the joint and a bulged area is formed. The current is stopped. The weld area cools under force and then the force is removed and the butt weld is complete. In flash welding the current is applied before the parts are brought together. This creates the flash.

Rods are welded end to end and then drawn into large wire coils using this process. It is fast reliable and repeatable. The bulged/upset material is normally removed by mechanical means. Grinding tools or files are frequently used for this.

JOULES LAW STATES:

In this equation the current, resistance and time are the variables. The controller or timer can alter both the time and the current. The resistance of the parts being welded is fixed but the resistance can be changed by altering the force/pressure used in the welding process. The question is which will have the largest affect upon the process. The answer is the current (I).

Per the definition of the Resistance Welding Manufacturers Alliance:

RESISTANCE WELDING IS THE JOINING OF METALS BY APPLYING

PRESSURE

AND PASSING

CURRENT

FOR A LENGTH OF

TIME

THROUGH THE METAL AREA WHICH IS TO BE JOINED

Reference: RWMA - Resistance Welding Manual 4th Edition

Page 4 of 5

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.