Spot Welding

Questions and Answers

This question was just answered a few weeks ago in this blog. Please refer to:

“HOW MUCH POWER IS USED IN RESISTANCE WELDING”

The actual value of power costs depends upon local power pricing and the power factor or the individual equipment and set up.

Reference: RWMA Resistance Welding Manual 4th Edition

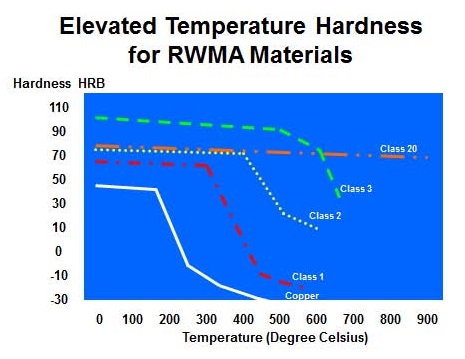

In North America the most commonly used electrode materials for galvanized steel are RWMA Class 1, 2 and 20. By the quantity Class 1 and 2 are the most popular by far. Class 20 finds applications where the fabricator has weld schedules that make use of its unique properties – good conductivity and high heat resistance. Class 20 is sold at a premium for its higher heat properties.

In a previous article there is a complete discussion of this topic:

“WHY IS RWMA CLASS 20 USED FOR SPOT WELDING GALVANIZED STEEL?”

Answers to the questions asked do not exist in the literaturer. This question has entered an area of academia and testing to reach definitive answers to the questions presented. This is beyond the scope of this blog.

Reference: RWMA - Resistance Welding Manual 4th Edition

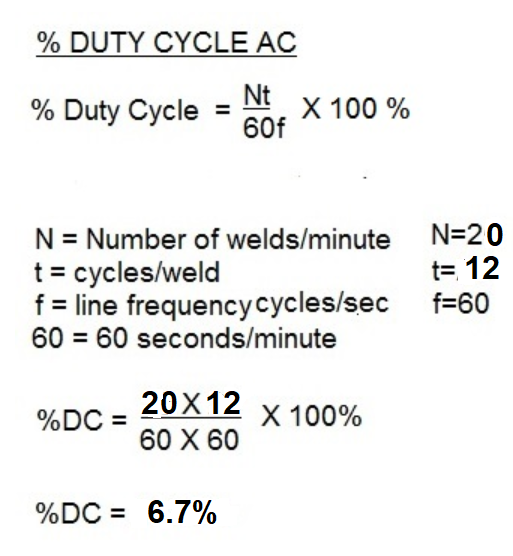

This question is asked often “How much power does my resistance welder use?” To answer this, we first need to calculate the Duty Cycle of the process. The formula for this is:

Proper alignment of the resistance welding electrodes is very important to insure proper force application and current flow through the electrode face. If not set up properly the part can be distorted and/or the electrode face can have exceedingly high current densities. This can result in distorted parts, expulsion and excessive electrode face wear.

Page 11 of 47

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.