Controls & Transformers

Questions and Answers

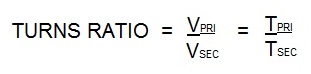

The transformer turns ratio in resistance welding reflects the number of secondary coil turns versus the number of primary coil turns. In AC transformers, there are many turns in the primary. The secondary has one turn. If there are 50 turns then the ratio is 50/1. Therefor the primary voltage will drop from 220 V and 100 amp input to 220/50 = 4 volts in the secondary. The equations for this are:

Vpri = Voltage on the primary Tpri = Turns in the primary coil

Vsec= Voltage on the secondary Tsec = Turns in the secondary coil

Power into Transformer equals power out of Transformer

Frequently transformers have tap switches or are built with parallel circuits. In this case a series bar can be installed to change the turns ratio or the tap can be changed to a different turns ratio.

To measure the actual turns ratio one must take the input output readings as shown above for the different taps or with the bar in or out to learn which is the turns ratio desired. This will depend upon the type of transformer you have.

Of course first look at the transformer drawing which will show the schematic with this information included.

Another article in this blog on this subject is:

WHAT IS TRANSFORMER TURNS RATIO FOR A SPOT WELDER?

Reference: RWMA Resistance Welding Manual, Chapter 19

This question is very involved. It depends upon what type of transformer (three phase, single phase, AC, DC). This blog does not get involved with machine design and build subjects. Contact your local machine sources or distributors for information and assistance.

Reference: RWMA Resistance Welding Manual 4th Edition

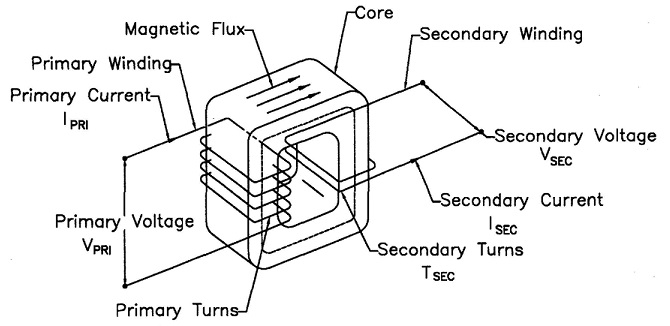

This question gets into the design of machine components. Design is beyond the scope of this blog. There are several articles describing the components of a transformer and their function in resistance welding. One for MFDC is shown below:

Schematic of Power Conversion In Control and Transformer of Mid Frequency Inverter

Reference: RWMA Resistance Welding Manual 4th Edition

Many resistance welding controls but not all have the ability to operate in more than one language. All controls are different and methods to change the language will vary.

AC CONTROL

Consult you control manual first. Then go to the control manufacturer, a local distributor or equipment dealer for assistance. Information will be available to answer this question.

This blog does not get into the operation of individual machines components.

Pressure is one of the major components of the welding process Pressure, Current & Time (PCT). In most weld schedules pressure is called out as a force value. Pressure is this same value as force but applied to the surface area of the electrode contact face.

Pressure is important because it provides the necessary mechanical force holding the two or more surfaces together during the welding sequence. This insures a good current path and contains the molten metal that may form to prevent expulsion.

The term “Pressure-Controlled Resistance Welding” is not familiar to me.

Page 6 of 39

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.