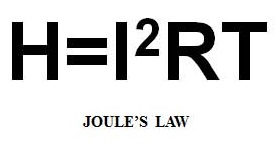

Bare steel and galvanized steel of the same thickness run at very similar weld schedule settings. The electrodes are the same. They vary in the amount of current or time applied due to the coating of galvanize (zinc) on the surface. This coating reduces the contact resistance and makes the overall resistance in the joint lower. More current or time must be applied to compensate for the reduced total joint resistance to reach the necessary temperature to form a nugget. The heat is generated by Joules Law:

The galvanized coating (Zinc) coats and alloys with the copper electrodes. This can result in:

• Increased the rate of electrode mushrooming

• Electrode face sticking to the part

• More frequent dressing

• Increased electrode wear

• Reduced electrode life

• Increased expulsion at weld initiation

Electrodes welding bare steel can make many thousands of welds. Welding galvanized steel they may only last a few hundred up to a two thousand before dressing is required.

Most operations work out schedules that allow for dressing or electrode changes at breaks or shift changes. In these operations they use current steppers to increase the current a few amperes each weld to match the electrode face growth until the next dressing or change. Then they reset the control counter and begin again.

Some operations use robotic dressers that move in every so many welds between part changes to slightly kiss the electrode face and renew the face continually. Then the current remains constant.

The basic resistance welding equipment can remain the same for bare or coated steel. The settings must change to compensate for the zinc coating. All resistance welders have the ability to do this. Due to the galvanized coating, dressing frequency enters into the process and must be addressed. Manual, pneumatic or automated systems can be used.

HAND DRESSER

Many modern controls have the stepper functions to compensate for electrode face growth. This is used to increase the time between dressing.

A related article in this blog is:

WHAT IS THE BEST METHOD TO SPOT WELD 16 GAGE ELECTROGALVANIZED SHEET METAL?

References: AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA - Resistance Welding Manual 4th Edition

CMW Inc. Welding Product Catalog